An internal combustion engine does not start under its own power but must be started externally. In the past, engines were started by a crank. Today, this function is performed by the starter, which is usually an electric motor, although hydraulic or pneumatic starters are also possible. Its responsibility lies in initiating the engine.

Primarily, the starter motor is engineered to endure as long as the engine. However, premature failure can occur, for instance, if it is not used correctly. To prevent damage, one should adhere to the following guidelines:

– Do not engage the starter when the clutch is engaged.

– Start only when the engine is at a standstill.

– Release the key immediately after the engine starts.

Repairing the starter: Clear indications of a faulty starter

Identifying a faulty starter is typically straightforward because the symptoms are quite distinct:

– Pressing the start button or turning the car key in the ignition yields no noticeable reaction.

– Hearing clicking or rotating sounds from the starter, but the engine fails to start. The starter pinion does not engage, thus failing to drive the engine.

Causes of a faulty starter:

Frequent operation of the starter with the clutch engaged or when the engine is still running can accelerate premature wear. However, there are other factors contributing to defects:

– Electrical connections of the starter are no longer functional.

– The engagement relay of the starter is defective or moves too sluggishly.

– The electric motor of the starter malfunctions.

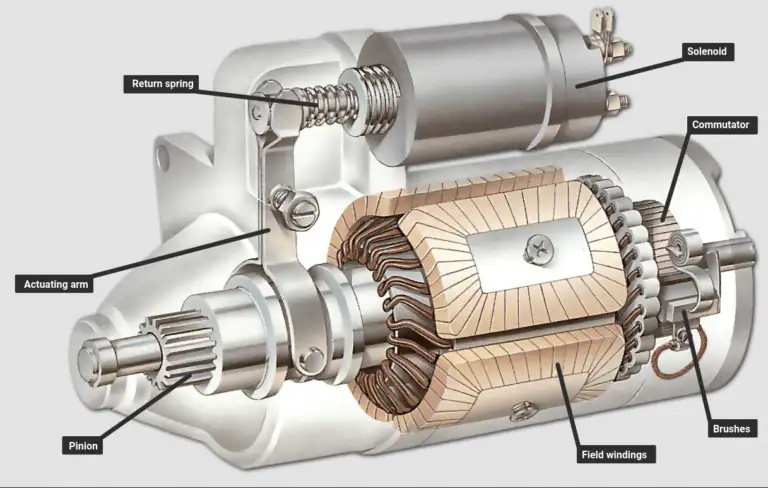

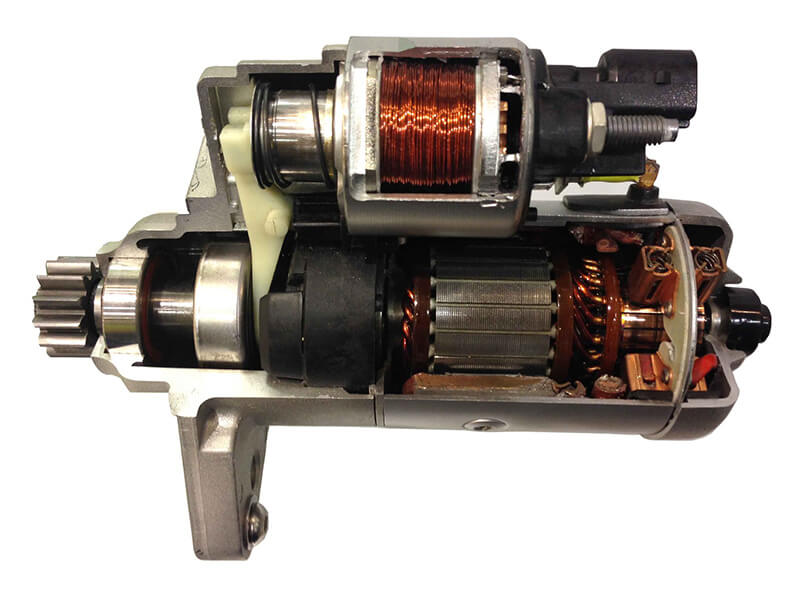

– Individual components of the starter, such as the starter pinion or the freewheel, suffer mechanical damage or wear.

The initial step is determining whether the starter itself is the issue or if the magnetic switch is defective. This requires a voltage meter to measure the starter’s voltage. If it reads 0 V, repairing the magnetic switch, not the starter, is necessary.

Starter repair – guidelines for experienced mechanics

Complete replacement of the starter may not always be necessary. Upon identifying the cause, only the problematic component needs replacement. The following steps outline repairing starter motors:

– Disconnect the negative terminal of the car battery.

– Remove the connecting cables and the retaining screws of the starter motor.

– Disassemble the starter to inspect for damage.

– Replace individual components of the starter motor for repair, or replace the electric motor entirely.

– Reattach the retaining screws, connect the cables, ensure correct seating of other existing components, and reconnect the battery.

Note: Sometimes, it is more prudent to have the starter repaired. Improper repairs by laypeople often result in further damage. Auto repair shops typically recommend complete starter replacement to avoid subsequent issues.

Starter repair: Costs and efforts summarized

The cost of repairing the starter motor varies based on the vehicle, region, and workshop prices. The actual component is not overly expensive: Material costs for repairing the starter range from approximately 70 to 200 euros. If your vehicle features an automatic start-stop system, anticipate higher prices due to the installation of stronger starter motors.

Repairing the starter typically takes between one and four hours. The effort depends on the accessibility of the starter. At an hourly rate of 100 euros, repair costs range from 100 to 400 euros. Total expenses for repairing the starter motor fall between 170 and 600 euros.

Leave a Reply